|

|

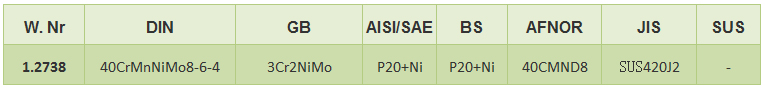

1.Comparable Standards

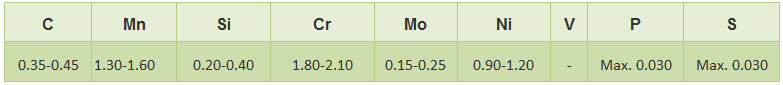

2. Chemical Analysis

3. Main Characteristics Chrome-manganese-nickel-molybdenum steel for hardening in air or in oil with good hardenability and good firmness during the heat. It is well-workable during the heat and well-workable in the soft-annealed state and it has good polishability. The steel has a high ability of the heat treatment into big depths (better than W.Nr.1.2311) with the balanced process of firmness around the whole cross-section. It is appropriate for nitriding and hard-chroming. 4. Applications Plastic injection moulds with high mirror surface requirements, large injection and compression moulds for plastic processing over 400 mm thickness such as bumpers, insturment panels, garbage containers, dashboards, waste bins, chairs, bottle crates, television cabinets etc., mould carrier frames for the plastic moulds, components for general mechanical engineering and tool manufacture, synthetic plastic moulding dies, pressure casting frames, hydro forming tools, structural components, shafts, blow moulds, extrusion dies for thermoplastics. 5. Supply Conditions Hardened and Tempered Normal HB 300-340 Contact our experienced sales team who will assist you with your inquiry for round bar, diameters, sawn plate and flat bar or special-shaped in 1.2738 plastic mould steel

|