Inconel625 (0Cr20Ni65Mo10Nb4) and GH128, GH4169,GH220 And other series of high temperature alloy structural steel forged parts products Inconel625 steel parts (0Cr20Ni65Mo10Nb4) refers to the alloy group which can be hot and cold processed. Its operating temperature range is 253-1320°C. The inconel625 has good mechanical properties and comprehensive, strong toughness index. Besides, it has high oxidation resistance andcorrosion resistance.It can be divided into solid solution strengthening alloy and aging strengthening alloy according to its heat treatment process. Its characteristics are as follows: 1. Solid solution strengthening type alloy Using temperature range is 900-1300°C, the highest oxidation temperature is 1320°C.For example, alloy GH128 has a temperature tensile strength of 850 Mpa, yield strength of 350 Mpa,1000°C the tensile strength of 140 Mpa and the elongation of 85%, 1000°C, 30 Mpa. Its stress lasting life is 200 hours , extension rate is 40%. Solid amalgamation gold is generally used for aviation, spaceflight, aerospace engine combustion chamber,Casing etc. 2. Aging strengthening type alloy Using temperature range is -253 to 253°C, it will usually be used for aviation, aerospace engine turbine disk and blade structure. Production of turbine disk operating temperature of the alloy is -253 to 700°C, it demands the steel has a good high temperature strength and fatigue resistance performance. For example: alloy GH4169 at 650°C has a maximum yield strength of 1000 Mpa; the alloy, which will be produced as turbine blades, reaches the using temperature of 950 ℃. GH220 alloy, at 950°C has the tensile strength of 490 Mpa, At 940°C, 200Mpa, its using life is more than 40 hours. Our company produces the GH128, GH220 GH4169 and other high temperature alloy structural steel series (Inconel625 0Cr20Ni65Mo10Nb4). Our production line including the forged rings, plates, pipe fittings, forgings and components will be mainly applied for the aerospace, aviation, nuclear power, petrochemical industry.

Contact our sales team to know more about all the series of high-temperature alloy structrual steel parts.

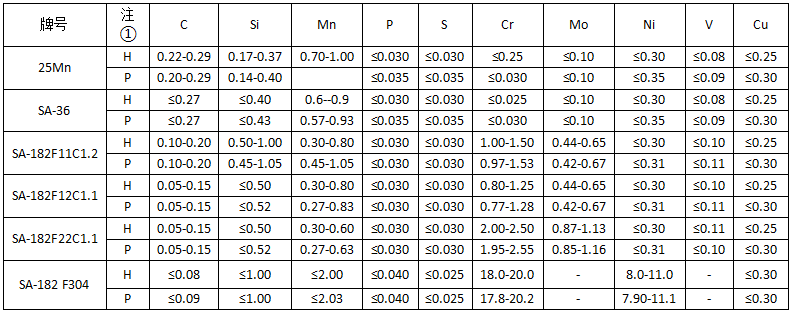

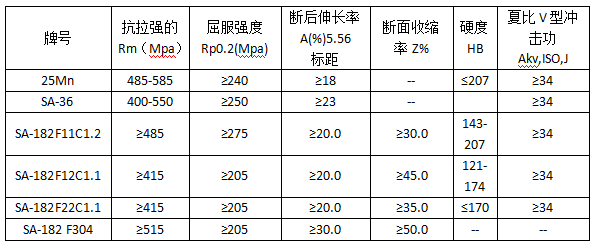

Supercritical power plant boiler roof hanging device Supercritical boiler roof hanging device is the boiler components which are of vital improtance to the boiler body. The power plant boiler roof hanging device is a connecting device which hangs the top of the boiler pressure parts on the steel structure. Such as the strainer, reheater, economizer, water wall,the top parts connecting pipe of boiler etc. Most of the boiler load hang on the roof of the steel structure by this device. Therefore,it is very important for the boiler to operate safely. Large pipe on the top, big plate girder, the crane beam, roof cladding frame lifting point and rigid beam lifting point, with which to ensure that there is no collision between each other. The quality of products must be guaranteed. Parts of supercritical, ultra-supercritical boiler parts in a large power plant, it mainly selects A335-P12 and SA335-P22 (high temperature area=, suing 15CrMo and 12 Cr1MoV, 1Cr18Ni9Ti, 25Mn, 35CrMoA, 4CrMo5ß6 and other materials. Through smelting rolling, forging heat treatment, pickling blasting finishing processing again by fine manufacturing testing coating, at last, produce the parts of products. The characteristics of the product: chemical compostion: Mechanical properties: Contact our sales team to know more about supercritical power plant boiler roof hanging device.

|

|

|