|

|

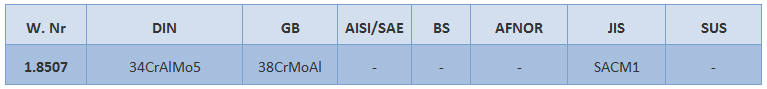

1. 1. Comparable Standards

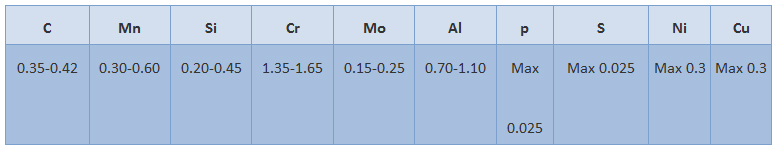

2. Chemical Analysis

3. Main Characteristics Advanced nitriding steel, has the very high nitriding performance and mechanical properties, good heat resistance and corrosion resistance, (getting) after nitriding treatment, can get high surface hardness, high fatigue strength and good resistance to overheating, no temper brittleness, cutting machining can be (getting), high temperature and working temperature can reach 500 ° C, but when the cold deformation plasticity is low, poor weldability, low hardenability, (getting) after quenched and tempered and nitriding commonly use 4. Applications Suitable for applications requiring excellent resistance to wear and abrasion. Typical applications include connecting rods, small extruders, valve stems, Injection Moulding Equipment, Hydraulic Cylinders, Gears And Pinions, Die Inserts, Valve and Gate Parts, Cams, Piston Pins, etc.This Nitriding steel is widely used in the automotive, textile and general engineering industries. With it resistance to wear 1.8507 is used in other applications such as brick press plates, clutch plates, gudgeon, track and shackle pins. 5. Supply Conditions

Contact our experienced sales team who will assist you with your inquiry for round bar, diameters, sawn plate and flat bar or special-shaped in 1.8507 cold work tool steel parts.

|