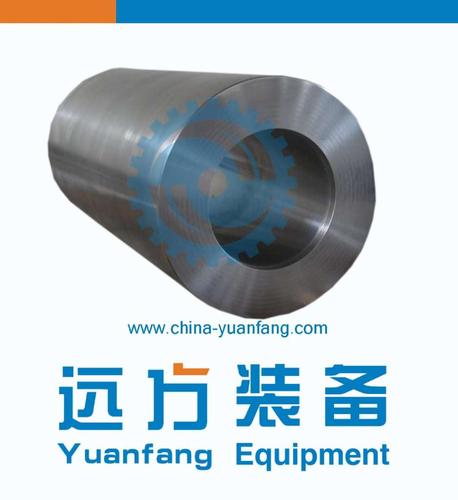

Non-magnetic retaining rings for 50MW-200MW power generator (represented by 50Mn18Cr5, 50Mn18Cr5N, 50Mn18Cr4WN and 1Mn18Cr1N Wind power and nuclear power is a part of wind turbines and nuclear power generating set and can not be replaced, therefore, the parts must have a long usage duration. The parts of wind power and nuclear power requires particular on chemical composition, mechanical property, smelting and the production line consists of forging, heat treatment and machining. Retaining rings are the one of the main parts of steam turbine unit. It plays an important role in the rotor end winding (protection, prevent deformation, displacement and eccentric). The retaining ring could bear the large centrifugal force, bending force and thermal force etc. from the rotor end winding and itself. In addition, retaining rings steel adopt deformation strengthening and has residual force. It is the most important part in the turbo generator set, which can bear high stress. In order to guarantee safe operation of the unit, retaining rings mus have high index of strength, plasticity and balanced mechanical properties and the smallest residual stress. For more than 300 MW unit retaining rings it requires yield strength requirements of minimum 1000MPa. Retaining ring work in a strong magnetic field and corrosive medium and has the working temperature below 100°C.

In order to reduce the end coil current losses and prevent over heat working temperature, retaining rings usually would be made of austenitic steel. Due to the special working condition and use conditions, retaining ring need to have higher ability to resist stress corrosion. The stress corrosion resistance plasticity of 1Mn18Cr18N series steel forgings and components is over 4 times higher than other similar products, at present in domestic, the mainly applied material for 300MW generator retaining rings are 1Mn18Cr18N series steel. Because of its production difficulty, there are only a few companies can produce in the world like mitsubishi heavy industries, and even in China there are few companies, which are able to produce such products. Our company is one of them. Our products reach the following index: Chemical components:

Mechanical properties:

Item I,II and item III recommend the steel grade: 50Mn18Cr5, 50Mn18Cr5N and 50Mn18Cr4WN; Item IV and V recommend the steel grade 1Mn18Cr18N. Our index:

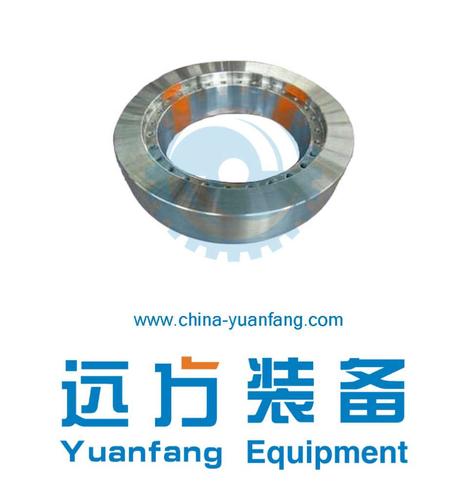

The principle of wind power is through the rotating of windmill blades which driven by the wind, the electricity is generated, as the rotation speed increases, by the power generator. Accelerating gearbox set is the main drive system and most important part of wind power generation set. It has following advantages: small volume, high-carrying capacity, long usage duration, stable function, low noise and easy temperature control etc.; Therefore, accelerating gearbox has high requirements for raw material, heattreatment and machining. Acceleration gearbox set consists of following components: inner ring gear, planetary gear shaft, planet gear, solar wheel, gear shaft, rack wheel, spline shaft, hollow shaft etc.,

The mainly used raw material is 18CrNiMo6/34CrNi3Mo. The manufacturing process is as follows:Steel smelting; forging; machining; carburized quenching(or quenching). Hot forging process requires the rate of forging to be more than 3, the non-metallic impurity not exceed:

Maximum slag content DS≤2 , Gas content in the forgings: O≤25ppm, N≤150ppm, H≤2ppm, Ca≤20ppm, AI/N ratio control between 1-3. The actual grain size ≥5 and no mixed crystal phenomenon. The mechanical properties of φ30*140 sample, which is oil cooling + 200 °C 840°C*2h*2h is hot and cold processed, can reach:

The heat-treatment should be prepared by 860 + 10 °C/ oil cooling and 660 + 10°C /furnace cooling before the forgings be carburized quenched; and reach the hardness HB180-220; Ultrasonic inspection according to the "ZAN 50615-1"; microstructure examination requirements: carbide level ≤3, martensite + retained austenite ≤3, the heart of ferritic ≤3. |

|

|